| Product ID | Product Image | Product Description | Product Code | Production status | Shipping Cycle | Gross item weight | MPQ | MOQ | Production in transit | Competitive purchases | Operation |

XB-X3501WR-06X-LPSN  3D 3D

Drawings Drawings |

|

22 * 5.35 * 11.2mm Piercing connector spacing 3.5mm/Board to Board connector pin spacing 3.5mm/Line to Board connector 6-position/Pin to Pin connector 6PIN/Wafer pin to Pin spacing 3.5mm | Normal | 1-2 weeks | 0.3g | 1000 PCS/disc | 5000 PCS | 10000 | Nothing |

| Product material | 1. Line to board connector | material quality |

| 2. The shell | UL 94V-2/UL94V-0 | |

| 3. Terminal | Phosphorus copper is silver plating / phosphorus copper gold plating | |

| 3. Rubber shell | LCP | |

| 4. The PIN needle No | Phosphorus copper is silver plating / phosphorus copper gold plating | |

| Product type features | rated current | 14A AC/DC |

| rated voltage | 400V AC/DC | |

| operating temperature range | -40°C±85°C | |

| contact resistance | 30mΩ | |

| insulation resistance | 100 mΩ | |

| withstand voltage | 1800V AC | |

| Environmental resistance | Cold resistance | -25±2℃ 96/h |

| resistance to effect of heat | 85 ± 2 ℃ 96/h | |

| Moisture resistance | 40 ± 2℃ relative humidity 90~95% 96 / h | |

| machine accessory | way to install | Welding wire / welding plate |

| Connector installation type: | Board installation | |

| Welding experiment | Dip the terminal foot in the flux for 5 seconds, then immerse the terminal foot in a 255 ± 5℃ tin furnace for 3 ± 0.5 seconds | The tin attached area shall exceed 95% of the immersion surface area |

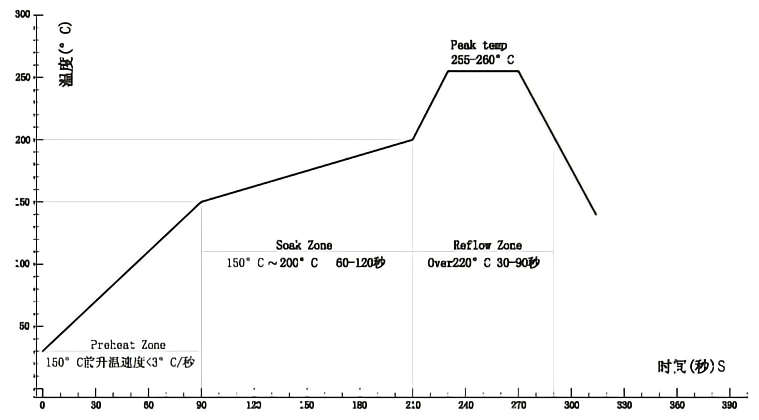

| Heat resistance of welding tin | The terminals shall be tested for tin resistance under the following conditions, and test the contact impedance after solder heat resistance | |

| Based on: EIA-364-56A | No cracks, scratches, and breaks | |

| Weldability temperature: 250 °± 5C | ||

| Time: 5s + / -1s | ||

| Reflow welding and wave crest welding experiments | wave-soldering | The recommended solder temperature is 260℃ (500°F) for a maximum of 5 seconds |

| Hand welding | The 30W flipping iron is used to control the temperature at 350℃, and the welding time is about 5 seconds | |

| Back furnace welding | The maximum temperature of SMT backwelding furnace is 260℃ and the temperature is 260℃, the maximum time shall not exceed 10 seconds | |

|

|

||

0769-82056828

0769-82056828

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website