| Product ID | Product Image | Product Description | Product Code | Production status | Shipping Cycle | Gross item weight | MPQ | MOQ | Production in transit | Competitive purchases | Operation |

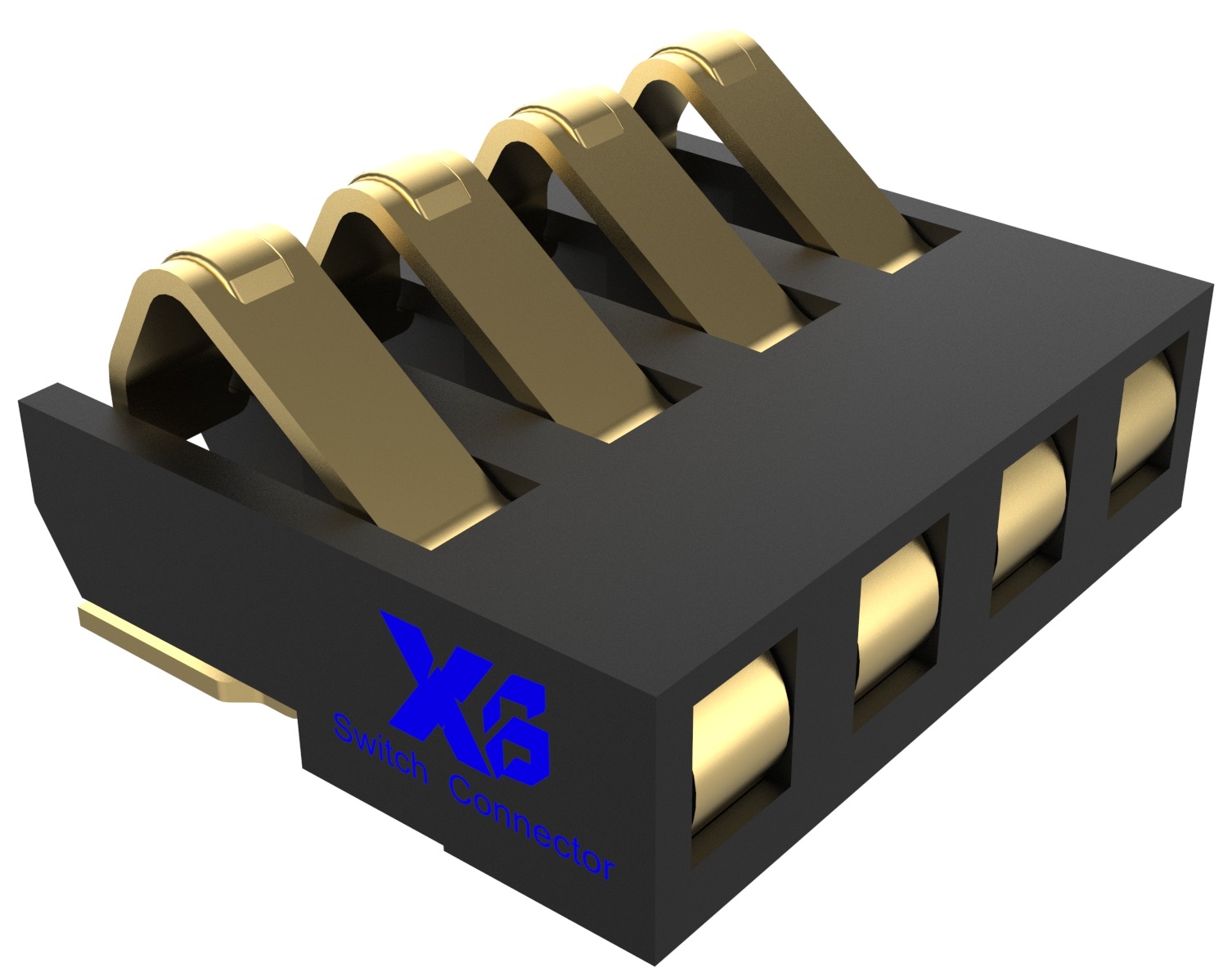

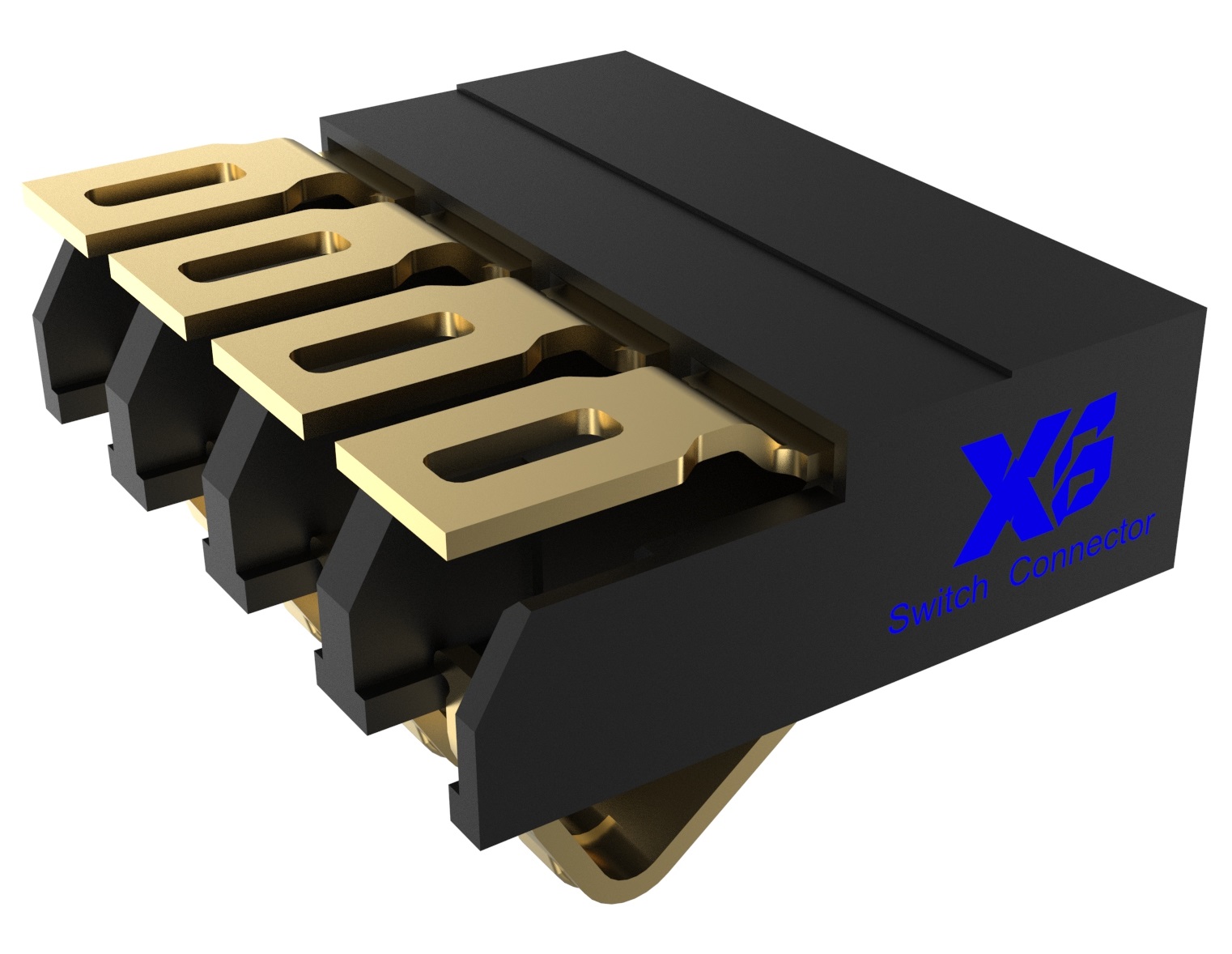

XB-BC-27-4P230  3D 3D

Drawings Drawings |

|

8 * 6.5 * 2.3mm spring battery holder/positive pressure spring battery holder male seat/low current spring battery holder/battery holder male seat spacing: 2.0/5P battery holder/spring connector | Normal | 4~7 days | 0.000 | 5000 | 50000 | 10000 |  Compatible Xibang |

||

XB-BC-27-4P230-X  3D 3D

Drawings Drawings |

|

8 * 6.5 * 2.3mm spring battery holder/positive pressure spring battery holder male seat/low current spring battery holder/battery holder male seat spacing: 2.0/5P battery holder/spring connector | Normal | 4~7 days | 0.000 | 5000 | 50000 | 10000 |  Compatible Xibang |

| product name | 1. Shrapnel battery holder | material quality |

| 2. The shell | LCP/PA66 UL 94-V | |

| 3. Touch | Brass Gold plated / Brass C2680 | |

| 5. Plastic parts | LCP/PA10T | |

| character of service | Use the temperature range | -40℃±85℃ |

| Maximum rating (resistance load) | 3A 60V DC | |

| Minimum rating (resistance load) | 1A 12V DC | |

| Electric performance | withstand voltage | 500V AC |

| insulation resistance | 100MΩ | |

| Contact resistance (initial / post-life) | 30mΩ max./100mΩ max. | |

| lasting quality | No load life | 5000 Times |

| Load life (maximum rated load) | 5000 Times | |

| project | test condition | function |

| Cold resistance | -40℃±3°C 96/h | No indication of any damage to the mechanical and electrical properties |

| resistance to effect of heat | 80℃±2°C 96/h | |

| Moisture resistance | 40℃± 2°C, 90 to 95% RH 96 / h | |

| Salt mist performance | 35°C ± 2°C 4h ± for 15 sec | |

| Temperature alternating experiment: | Like the icon, in the environment, cycle 5 times, then placed in the normal environment, and test after 30 minutes. | |

|

|

||

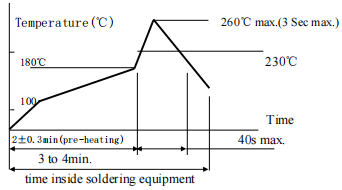

| Thermal test for return heat welding: | test condition | function |

|

|

The body has no deformation, and can be satisfied with the mechanical and electrical performance | |

| * Temperature refers to the temperature of the PC plate surface | ||

| * The PC plate is 1.0 mm thick | ||

| No lead tin test | ||

| Ingredients: tin 96.5% copper 3% silver 0.5% | ||

| Number of reflow welding: 1 time | ||

0769-82056828

0769-82056828

XB-BC-27-4P230

XB-BC-27-4P230

ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website