| Product ID | Product Image | Product Description | Product Code | Production status | Shipping Cycle | Gross item weight | MPQ | MOQ | Production in transit | Competitive purchases | Operation |

XB-DIN-G-5P  3D 3D

Drawings Drawings |

|

7.8 * 15mmDIN connector/BMW head socket/BMW head seat/5P terminal male seat/5P male head/5PIN plug | Normal | 1-2 weeks | 0.3g | 1000 pieces/bag | 5000 | 10000 |  Compatible Xibang |

||

XB-DIN-G-5P-X  3D 3D

Drawings Drawings |

.png) .png) |

7.8 * 15mmDIN connector/BMW head socket/BMW head seat/5P terminal male seat/5P male head/5PIN plug | Normal | 1-2 weeks | 0.3g | 1000 pieces/bag | 5000 | 10000 |  Compatible Xibang |

| product material | 1. DIN connector | material |

| 2. Plastic | PBT | |

| 3. Shell | PBT | |

| 6. Terminal | Brass/Silver Plated/Gold Plated | |

| Operating temperature range | -20°C±70°C | |

| Maximum rating (resistive load) | 4A 30V DC | |

| Minimum rating (resistive load) | 2A 12V DC | |

| electrical properties | withstand voltage | 300V AC |

| Insulation resistance | 100mΩmax | |

| Insertion force | 25N~45N | |

| Contact resistance | 30mΩmax | |

| Durability | no load life | 5000 times |

| load life | 5000 times | |

| Environmental resistance | Cold resistance | -40±3℃ for 96h |

| Heat resistance | 80±2℃ for 96h | |

| Humidity resistance | 40±2℃, 90 to 95%RH for 96h | |

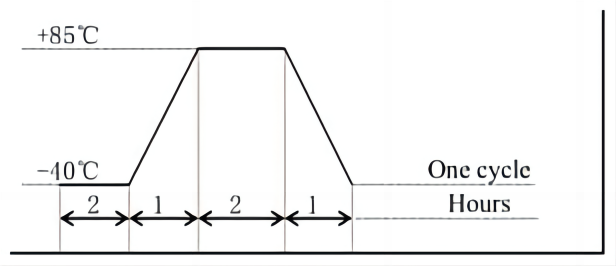

| 1. Temperature change experiment | According to the figure below, after 5 cycles, the test is carried out after 30 minutes under normal conditions. | |

| 3. Temperature distribution |

|

|

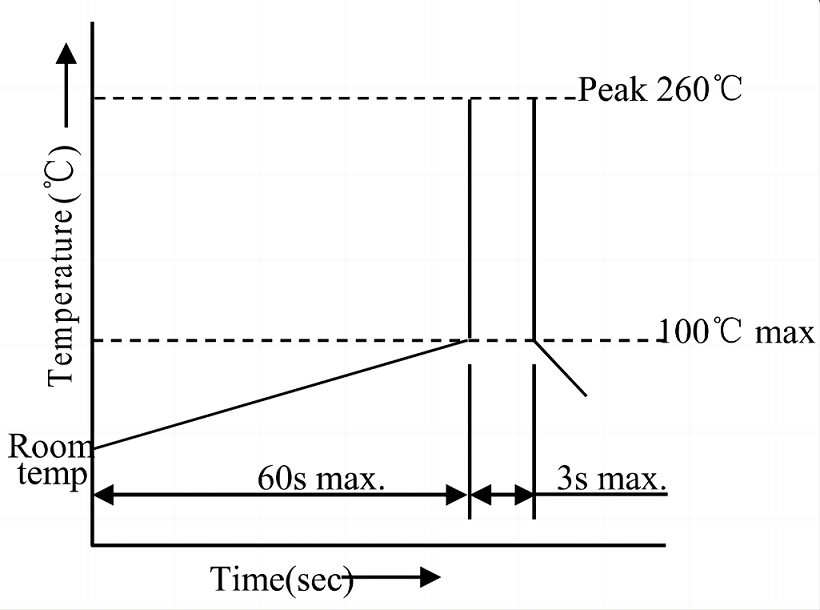

| When hand soldering | soldering temperature | 260°C max. |

| Preheat time | 60 seconds maximum | |

| Continuous immersion time | 3 seconds maximum | |

| Welding times | 1 | |

| Durability | ||

| Solderability Test | The top of the terminal is immersed in the solder pool to a depth of 2mm at a temperature of 250±5°C for 3 seconds | More than 95% of the surface of the immersed part will be covered by tin |

| Lead-free tin test composition: tin 96.5% copper 3% silver 0.5% | ||

| Solder resistance test | When hand soldering, the temperature should be controlled at 300±5°, and the time should be 3±0.5s, but abnormal pressure should not be applied to the terminals | The body has no deformation and can meet the mechanical and electrical performance |

| Lead-free tin test composition: tin 96.5% copper 3% silver 0.5% | ||

| Corrugated welding | When using a low-wave oven for soldering, the maximum temperature setting is 260°C | |

|

|

||

| Preheating temperature: The ambient temperature of the soldering surface of the PC board is up to 100°C | No damage to appearance or mechanical function | |

| Warm-up time: up to 60 seconds | ||

| Soldering temperature: up to 235°C | ||

| Continuous dipping time: up to 3 seconds | ||

| Number of welds: up to 1 time | ||

0769-82056828

0769-82056828

XB-DIN-G-5P

XB-DIN-G-5P

ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website