| Product ID | Product Image | Product Description | Product Code | Production status | Shipping Cycle | Gross item weight | MPQ | MOQ | Production in transit | Competitive purchases | Operation |

XB-ST-0-102-003-RS  3D 3D

Drawings Drawings |

.jpg) .jpg) |

8.3 * 5.2 * 12.75mm 90 ° swing switch side insertion/one on/one off second gear button switch/side toggle switch/second gear toggle switch/second gear rocker switch | Normal | 4-7 days | 0.000 | 50000 | 2000 | 10000 |  Compatible Xibang |

||

XB-ST-0-102-003-RS-X  3D 3D

Drawings Drawings |

|

8.3 * 5.2 * 12.75mm 90 ° swing switch side insertion/one on/one off second gear button switch/side toggle switch/second gear toggle switch/second gear rocker switch | Normal | 4-7 days | 0.000 | 50000 | 2000 | 10000 |  Compatible Xibang |

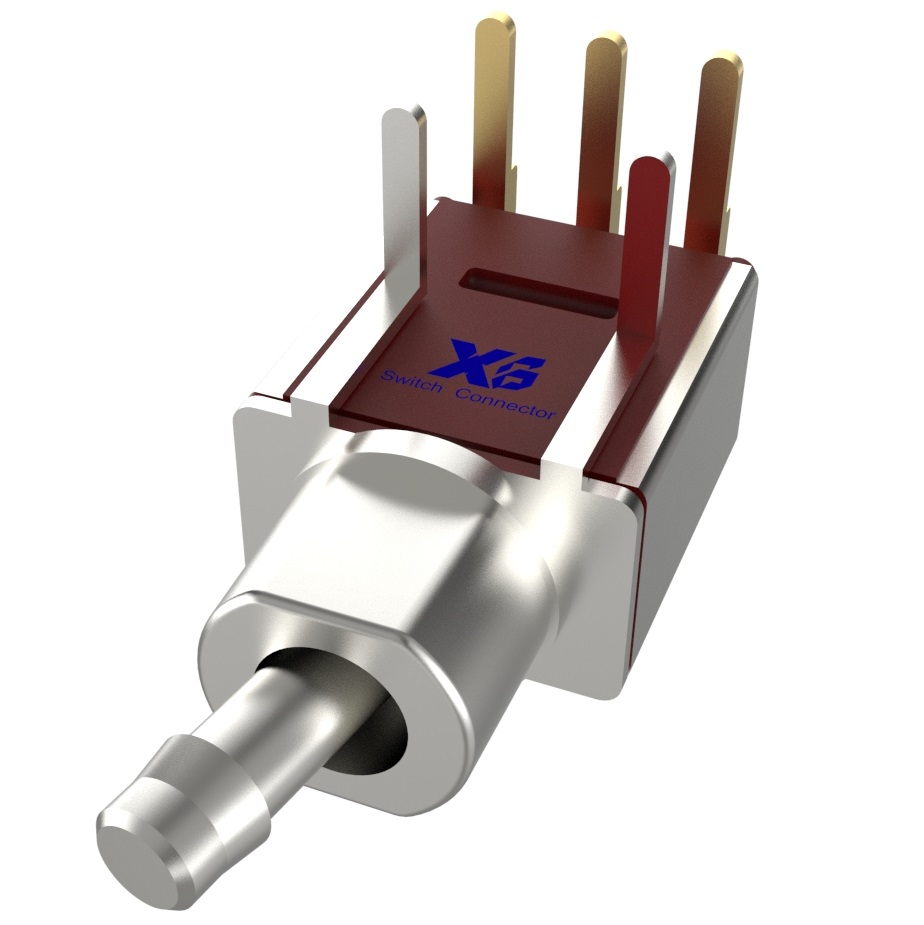

| product material | 1. Toggle switch | Material |

| 2.Lid | SUS | |

| 3.Plastic | PA66/UL94V-0 | |

| 4. Pin | Brass silver plated | |

| 5.Metal handle | Copper/zinc alloy | |

| Operating temperature range | -30°C±85°C | |

| Maximum rating (resistive load) | 10A 250V AC | |

| Minimum rating (resistive load) | 5A 125V AC | |

| Electrical properties | Withstand voltage | 1500VAC |

| Insulation resistance | 100mΩmax | |

| Solderability test | 230±10°C | |

| Contact resistance | 30mΩmax | |

| Durability | No load life | 5000 times |

| load life | 5000 times | |

| Heat resistance test | 85±2°C/96h | |

| Cold resistance test | -25±3°C/96h | |

| Humidity test | 40±2°C relative humidity 90%~95%/96h | |

| Salt spray test | Test with 5% salt water concentration, salt spray deposition ml/802cm, 2h volume 1.5, indoor temperature 26°C/humidity 26°C, pH value 6.2 for 12 hours | There are no abnormal conditions/test passing requirements for salt spray 12H products |

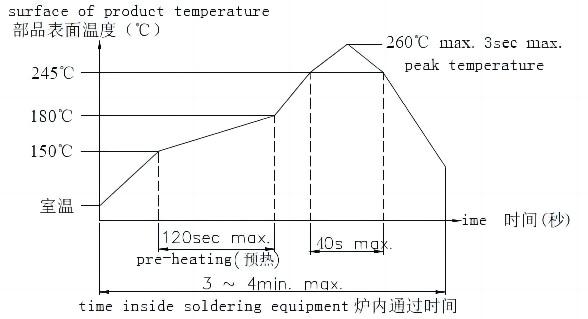

| welding conditions | 1. The temperature control of manual welding is 350±5°C, and the time is ≤3 seconds. | The body has no deformation and can meet the mechanical and electrical performance |

| 2. The temperature of the soldering furnace is controlled at 260±5°C, and the furnace passing time is ≤3 seconds. Note: The above conditions are the PWB temperature on the upper surface of the part. Due to the different materials, sizes, thicknesses, etc. of the PWB, the switching surface of the PWB The temperatures obtained will vary greatly, therefore, be careful not to allow the switch surface temperature to exceed 260°C | ||

| 3. Other precautions: (1) During the welding process, do not use solvents or similar products to clean the switch (2) Prevent flux from penetrating from the top of the switch | ||

|

|

||

0769-82056828

0769-82056828

XB-ST-0-102-003-RS

XB-ST-0-102-003-RS

ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website