|

Product material

|

1.Drehschalter

|

PA46

|

|

2.cover

|

SUS

|

|

3.Spring

|

SUS

|

|

4.Base

|

PA46

|

|

5.Contact

|

F.ag/Brass Plating silver

|

|

6.Terminal

|

Brass Plating silver

|

|

|

Operating temperature range

|

-25 ℃ to 85 ℃

|

|

Maximum rating (resistive load)

|

100mA

|

|

Minimum rating (resistive load)

|

12v

|

|

|

Electrical performance

|

Withstand voltage

|

100V AC for 1 minute

|

|

insulation resistance

|

30MΩ min.

|

|

|

Durability

|

No load life

|

25,000 cycles(10mA 5V DC)

|

|

Load life

|

25,000 cycles

|

|

|

Environmental resistance

|

Cold resistance

|

-40±2℃ for 96h

|

|

Heat resistance

|

85 ±2℃ for 96h

|

|

Moisture resistance

|

40±2℃, 90 to 95%RH for 96h

|

|

|

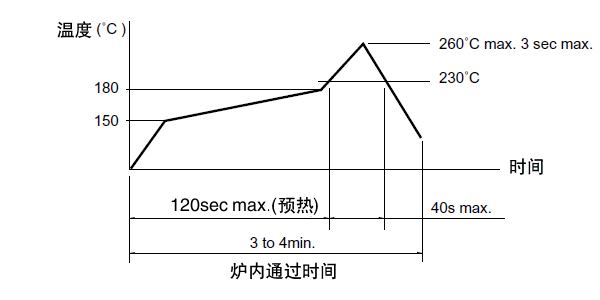

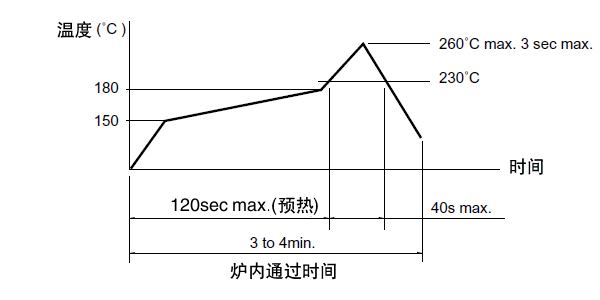

Welding conditions

|

|

|

|

During reflow soldering

|

|

|

|

1. Heating method

|

Up and down heating mode of far infrared heating

|

|

2. For temperature measurement

|

φ zero point one φ 0.2 CA (K) or CC (T) measuring position is measured at the welding connection part (copper foil surface) and fixed with heat-resistant tape

|

|

3. Temperature distribution

|

|

|

|

|

(1) The above conditions refer to the surface temperature of parts of printed circuit board. According to the material, size, thickness, etc. of the circuit board, the temperature of the circuit board and the surface temperature of the switch will be very different. For the surface temperature of the switch, please use it within the above conditions.

|

|

(2) According to the type of veneer welding groove and different conditions, the results are different. Please fully confirm before use.

|

|

|

During manual welding

|

welding temperature

|

350±5℃

|

|

Welding time

|

3s max.

|

|

Number of welding

|

1 time

|

3D

3D

Drawings

Drawings

0769-82056828

0769-82056828

XB-XZ-108N

XB-XZ-108N

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website