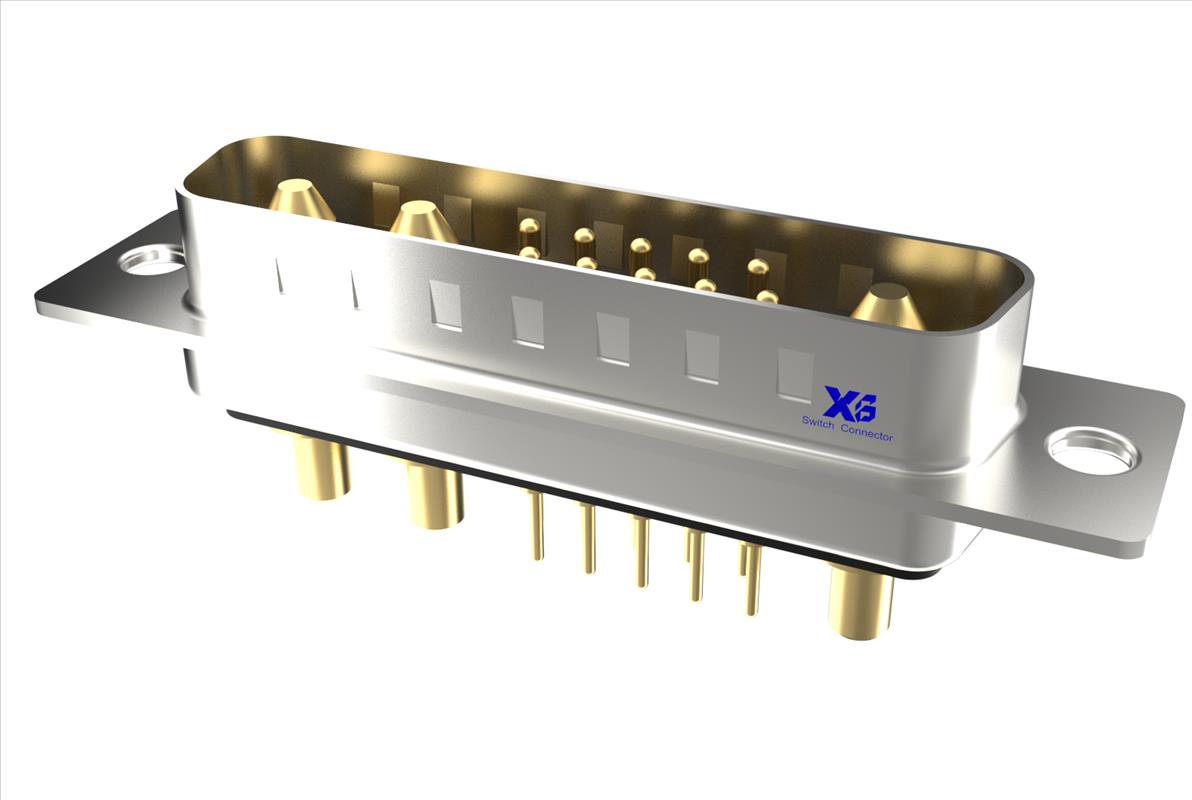

| Product Material | 1. D-SUB connector | Material | ||

| 2. Shell | UL94V-0 | |||

| 3. Terminals | Phosphor copper silver plated/Phosphor copper gold plated | |||

| 3. Plastic shell | Phosphor Bronze | |||

| Product Type Features | Rated current | 3A | ||

| Rated voltage | 250V AC | |||

| Operating temperature range | -55°C±125°C | |||

| Contact resistance | 30mΩ | |||

| Insulation resistance | 10mΩ | |||

| Withstand voltage | 1000V AC | |||

| Environmental resistance | Cold resistance | -25±2℃ 96/h | ||

| Heat resistance | 105±2℃ 96/h | |||

| Moisture resistance | 35±3℃Relative humidity 90~95% 96/h | |||

| Mechanical accessories | Installation | Wire/Board Welding | ||

| Connector Mounting Type: | Board Installation | |||

| Solderability test | Immerse the terminal pins in the flux for 5 seconds, then immerse the terminal pins in a 230±5℃ tin furnace for 5±0.5 seconds | The tin attached area should exceed 95% of the immersed surface area | ||

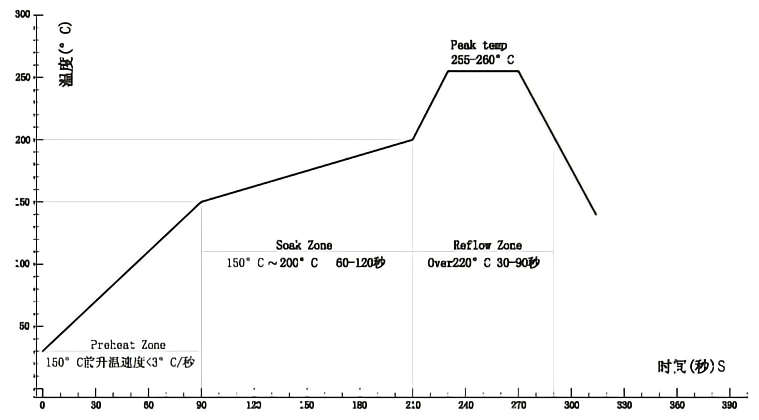

| Solder heat resistance | The terminals should be tested for tin resistance and solder heat resistance under the following conditions and then tested for contact impedance. | |||

| Based on: EIA-364-56A | No cracks, scratches or breaks | |||

| Solderability temperature: 245°±5C | ||||

| Time: 3s+/-0.5s | ||||

| Reflow and wave soldering experiments | Wave Soldering | The recommended soldering temperature for DIP type is 260°C (500°F) for a maximum of 5 seconds | ||

| Hand welding | Use a 30W soldering iron to control the temperature at 380°C and solder for about 3 seconds | |||

| Reflow | The maximum temperature of the SMT reflow oven is 260°C. When the temperature is 260°C, the maximum time does not exceed 10 seconds. | |||

|

|

||||

-

- Switch

Tact Switch Side stent The plug-in The patch

Slide Switch High current Slide Switch Mini Slide Switch Slide Switch horizontal Vertical Slide Switch Slide Switch rocker type Slidide switch waterproof

Push Switch Vertical series SMT series Horizontal series Side sticker series

Dip Switch DIP curved foot type DIP key type DIP patch 1.27 IC type SMD IC plug-in type DIP flat dial type Tristate equation 2.54 Horizontal double connection

Micro Switch Large micro switch Medium micro switch Small micro switch Micro switch (waterproof)

Lamp Switch Plug in DIP series SMD series Side press horizontal series

Tilt Sensor Switch Spring type Ball type

Detector Switch Plug in DIP series SMD series

Multi -function Switch Rotary coding switch 7.2X7.2 7.4X7.4 10X10

Door lock switch Button switch Flashlight switch 8.3X8.3 12X8 12X10 12X12 12X12 (Tactical) 12X14 12X17 13X18 13X23 Circular switch 12.8X17.5

Straight key switch 1P1T 1P2T 2P2T 4P2T 6P2T 8P2T 10P2T 12P2T 14P2T 16P2T

Toggle switch Hook Switch Rocker switch Keyboard switch Rotary switch Dental punch Photoelectric switch Photoelectric switch Optocoupler element Remote control signal receiving module Plastic fiber optic terminals

Potentiometer EC coding potentiometer Encoder

Metal button switch XB PBM(8mm) XB PBM(10mm) XB PBM(12mm) explosion-proof XB PS(12mm) XB PBM(16mm) XB PBM(19mm) XB PBM(22mm) XB PBM(25mm) XB PBM(30mm) XB PTM (19mm) lithium battery XB PS (19mm) high current XB PSM high current XB ESM emergency stop switch XB TM(16mm) XB PAM

Blade switch Emergency stop switch Keyswitch Electronic lock Scanning lock Dual function lock

- Socket

Audio Jack 2.5 Audio socket DIP 2.5 Audio socket SMD 3.5 Audio socket DIP 3.5 Audio socket SMD 6.35 Audio Jack Sink board audio socket Waterproof audio socket 3.5 Audio plug 2.5 Audio plug 6.35 Audio plug 4.4 3.5 Audio socket 4.4mm headphone plug

DC power Jack DC plug DC socket sinking plate DC socket vertical DC socket patch DC socket horizontal type DC socket with switch DC socket magnetic suction type

USB socket USB 2.0 Type A Female Connector USB 3.2 A-type connector Micro USB 2.0 Connector Mini USB 2.0 Connector TYPE C Connector Magnetic USB connector IEEE 1394 connector USB 2.0 B-type connector Micro USB 3.2 Connector Waterproof Micro connector USB 3.2 B-type connector

Blade battery holder Base spacing 2.0 Spacing between male seats 2.0 Base spacing 2.5 Spacing between male seats 2.5 Spacing between male seats 5.0 Base spacing 5.0 Distance between male and female seats 2.7 Parent seat spacing 7.5 Spacing between male seats 7.5 Spacing between male seats 3.0 Base spacing 3.0

Bullet battery holder Positive pressure type Side pressure type Mother seat Battery box

DP socket HDMI socket RJ45 socket RJ11 RJ12 RJ45

AC socket Button battery holder RCA socket Optical socket Launcher Receiver

PCB card socket CS socket - Connector adapter

BTB Connector Spacing 0.35mm Spacing 0.4mm Spacing 0.5mm Spacing 0.635mm Spacing 0.8mm Spacing 1.0mm Spacing 1.27mm Spacing 2.0mm Spacing 2.54mm Spacing 3.0mm Spacing 3.7mm Spacing 4.0mm Spacing 5.4mm Spacing 6.2mm Plug connector Jianniu connector

SD/SIM card seat Connector 2FFSIMCARD 3FFSIMCARD 4FFSIMCARD SDCARD SMARTCARD TFCARD SD card holder 4.0 NANO SIM card holder SIM card holder SD card holder

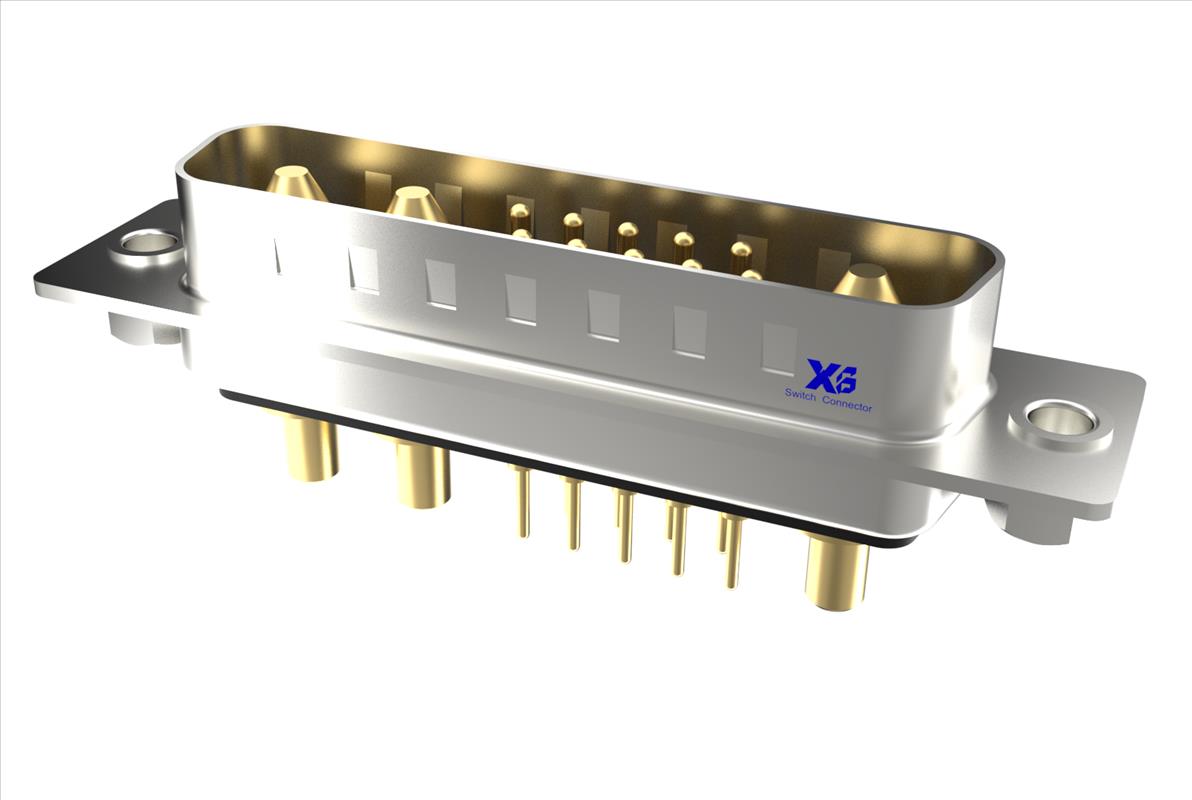

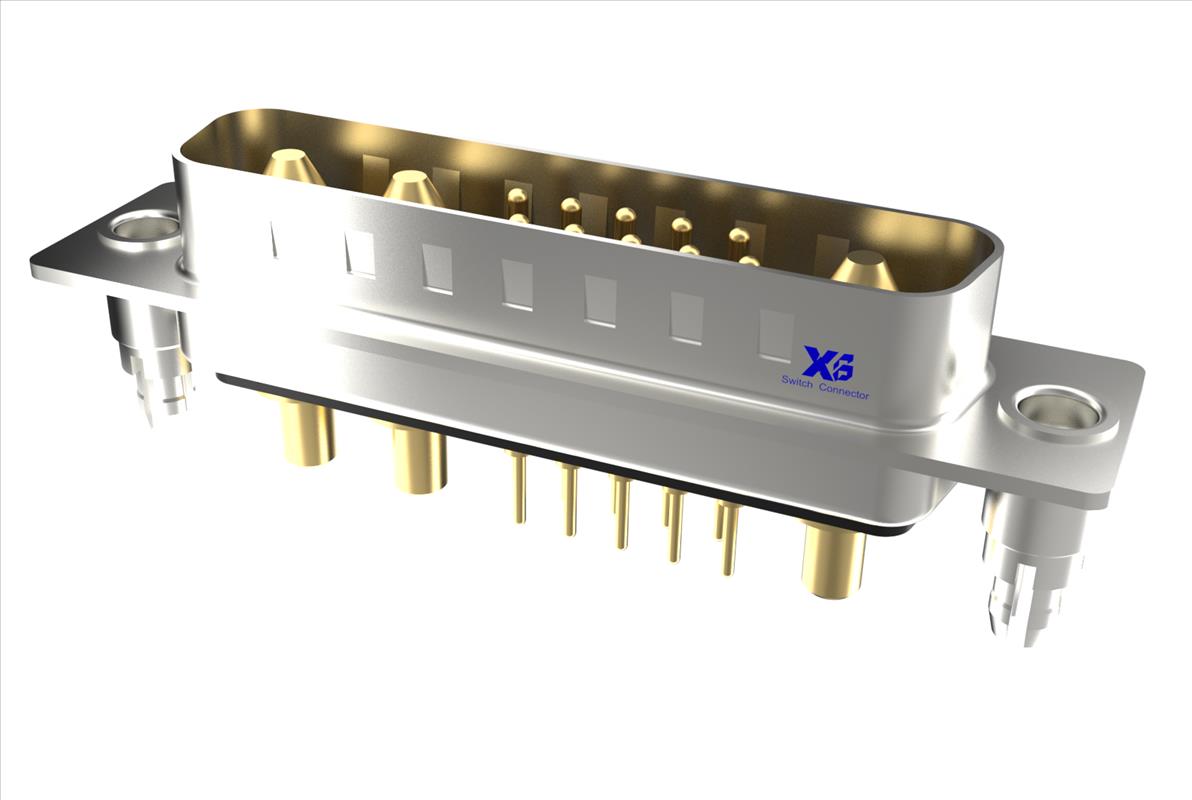

D-SUB Connector D-SUB connector combination

FFC/FPC Connector Spacing 0.3mm Spacing 0.5mm Spacing 1.0mm Spacing 1.25mm 间距0.8mm

Line to board connectors Spacing 0.6 Spacing 0.8 Spacing 1.0 Spacing 1.2 Spacing 1.25 Spacing 1.27 Spacing 1.5 Spacing 1.8 Spacing 2.0 Spacing 2.5 Spacing 2.54 Spacing 3.0 Spacing 3.5 Spacing 3.96 Spacing 4.0 Spacing 4.2 Spacing 5.0 Spacing 5.08 Spacing 5.7 Spacing 6.35 IDC connector RAST connector Jianniu connector Distance 7.92 7.55mm spacing Wire to board connector Wire to board crimping shell

Line to Line Connector DIN connector DIN plug DIN socket

XLR connector Automotive connectors Car mounted connector

Pogo Pin Connector Magnetic suction Pogo Pin Side sticker Pogo Pin SMT Single row Pogo Pin Double row Pogo Pin Single headed Pogo Pin Side insertion Pogo Pin Positive pressure Pogo Pin

EC connector EC2 connector EC3 connector EC5 connector EC6 connector EC8 connector

XT connector XT30 XT60 XT90

LED connector Quick plug connector LED bulb connector T8/T5 lamp connector Spotlight connector Downlight connector Other LED connectors

RF connector Sata connector Banana plug connector Circular connector A-type B-type C-type D-type

Floating connector 0.5mm 0.635mm 2.54mm 4.0mm 6.5mm

Card edge connector 0.8mm 1.0mm

Bus connector 0.8mm 1.0mm 1.27mm 2.0mm 2.54mm 3.96mm 5.08mm Circular hole IC socket

Pin connectors 0.8mm 1.0mm 1.27mm 2.0mm 2.54mm 3.96mm 5.08mm Fish eye terminal connector Circular hole IC socket

LED module

- Switch

-

-

About Us

-

Products

-

Switch

Socket

Connector adapter

-

-

Application

-

Service

-

News

-

Contact Us

0769-82056828

0769-82056828

XB-13W3-PPVXXX20B00

XB-13W3-PPVXXX20B00 3D

3D Drawings

Drawings

ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website